By Ben Watson

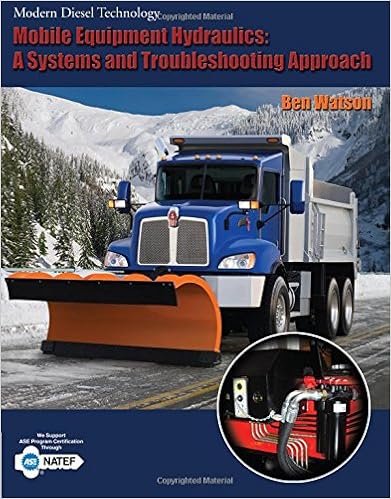

Designed for the mandatory path on hydraulics present in diesel know-how and heavy apparatus courses, cellular apparatus HYDRAULICS: A structures AND TROUBLESHOOTING technique, takes a realistic method of the certainty of fluid strength / hydraulic structures. rather than targeting the layout problems with fluid energy platforms this e-book techniques hydraulics extra like a technician could to method a process that calls for upkeep or troubleshooting. approximately all aspiring diesel technicians obtain education during this topic, that is one in all seven parts of research famous through NATEF in diesel know-how. assurance features a research of terminology, commercial criteria, symbols and easy circuitry layout as with regards to fluid strength. Examples are drawn from real apparatus that's suitable to this system of research, even if or not it's heavy truck, earth-moving, or agricultural apparatus.

Read or Download Mobile Equipment Hydraulics A Systems and Troubleshooting Approach (Modern Diesel Technology) PDF

Best repair & maintenance books

Kawasaki ZR550 and 750 Zephyr Fours '90 to '97

There's a Haynes guide for many renowned family and import automobiles, vans, and bikes. by way of undertaking entire tear-downs and rebuilds, the Haynes employees has found all of the difficulties proprietors will locate in rebuilding or repairing their motor vehicle. Documenting the method in 1000s of illustrations and costly step by step directions makes each professional tip effortless to persist with.

Hemivariational Inequalities: Applications in Mechanics and Engineering

The purpose of the current booklet is the formula, mathematical research and numerical remedy of static and dynamic difficulties in mechanics and engineering sciences concerning nonconvex and nonsmooth power services, or nonmonotone and multivalued stress-strain legislation. Such difficulties bring about a brand new form of variational varieties, the hemivariational inequalities, which additionally bring about multivalued differential or necessary equations.

Hovercraft Technology, Economics and Applications

The amphibious versatility, marine velocity and coffee footprint strain have given the hovercraft a task in really good functions. between them are seek and rescue, emergency clinical providers, army and arctic operations, icebreaking, patrol, legislations enforcement, ferries, and leisure actions resembling racing.

Additional resources for Mobile Equipment Hydraulics A Systems and Troubleshooting Approach (Modern Diesel Technology)

Example text

These pumps alter their flow rate based on changes in the pressure within the system. has long since been incapable of providing sufficient flow for the system to function at a proper speed. Although it may be a bit simplistic to say, pressure in the system determines the power in the system. Pressure is directly related to the amount of work the system can do. Flow is related to how fast the system FLUID FLOW IN THE PUMP As previously mentioned, the pump is the heart of the hydraulic system. Fluid is drawn in from the lowpressure area as the inlet is moved into the gear chambers, vane chambers, or piston cylinders.

Just like its affect on flow rate, if the valve has been sized properly the flow rate of the system will not be affected and therefore the velocity of the fluid will not be affected. FLUID DAMAGE IN THE DIRECTIONAL CONTROL VALVE With little in the directional control valve to add contamination or heat, there is nothing to damage the fluid. The valve itself however can be significantly damaged by contamination of the fluid from other sources (see RS 1-4, p. 41). CYLINDER Many types of actuators exist, given the great variety of hydraulic systems worldwide.

Building a Basic Cylinder or Hydraulic Motor Circuit: A Non-Math Explanation of Operation 29 A C B Figure 2-35 In this set of drawings, the system uses an open center directional control valve. Drawing ‘‘A’’ shows the valve in the center position. On the pump side of the system, fluid is flowing freely from the pump through the directional control valve and back to the reservoir. The pressure in the pump side of the system is either minimal or zero. On the actuator side of the system, fluid can move in a free manner back and forth to or through the actuator.